Blast Chiller Temperature Log

Q Tbn And9gcsfeke0adbyvpln Lyb0ybcncn2nzvkn4uciowixtetfuhy7wwr Usqp Cau

Tecnodom Technochef Professional Blast Chiller 7 Gn 1 1 Trays Mod Att07 Cold Storage Rooms And Refrigerators Technochef It

Q Tbn And9gcqllyjipqxcsgtdeovy8ofzjelijtpaazucfbmoxlvqpyenraow Usqp Cau

Haccp Plan

Constancy Precision Refrigeration Ifp Chilling Technology Application Overview King Son Instrument Tech Co Ltd

Delfield Cv15e2 32 Self Contained Blast Chiller Shock Freezer 154 Lb 1 Lb

Blast Chiller the food does not reach the required temperature;.

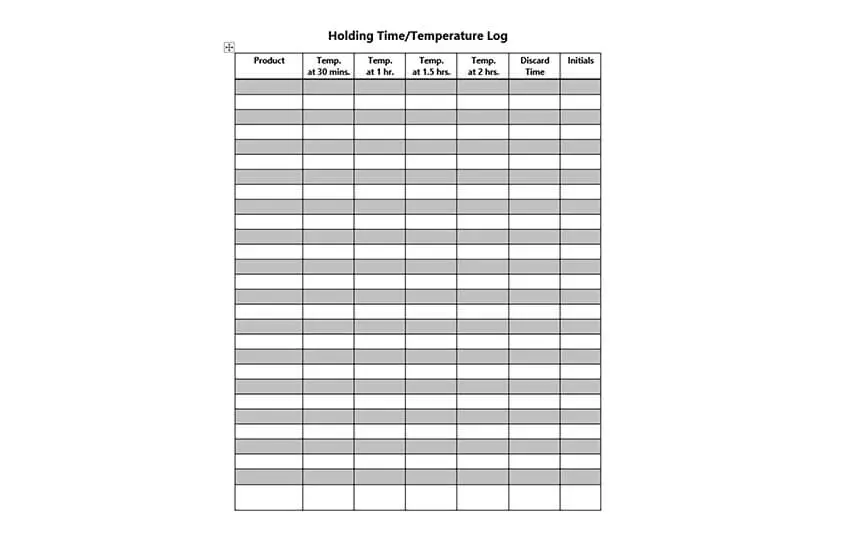

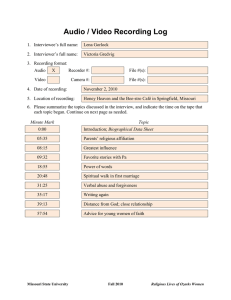

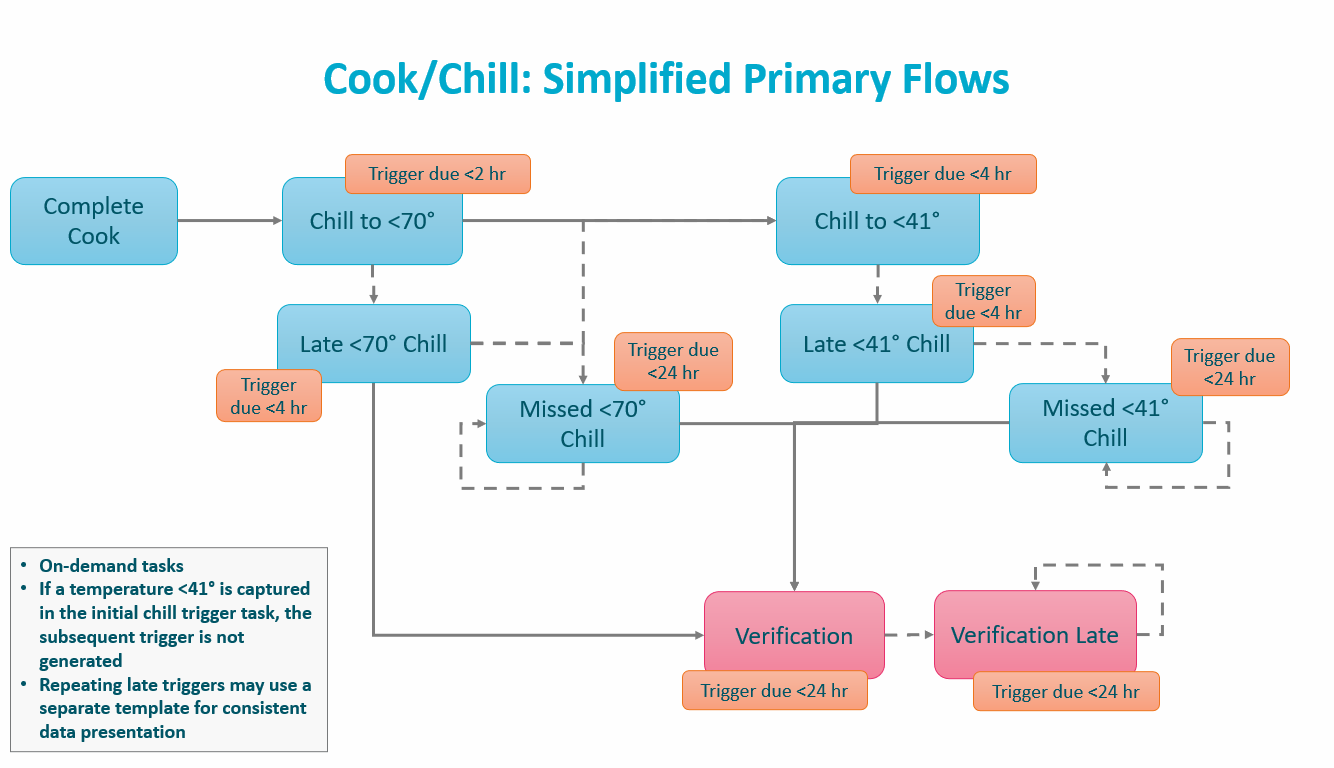

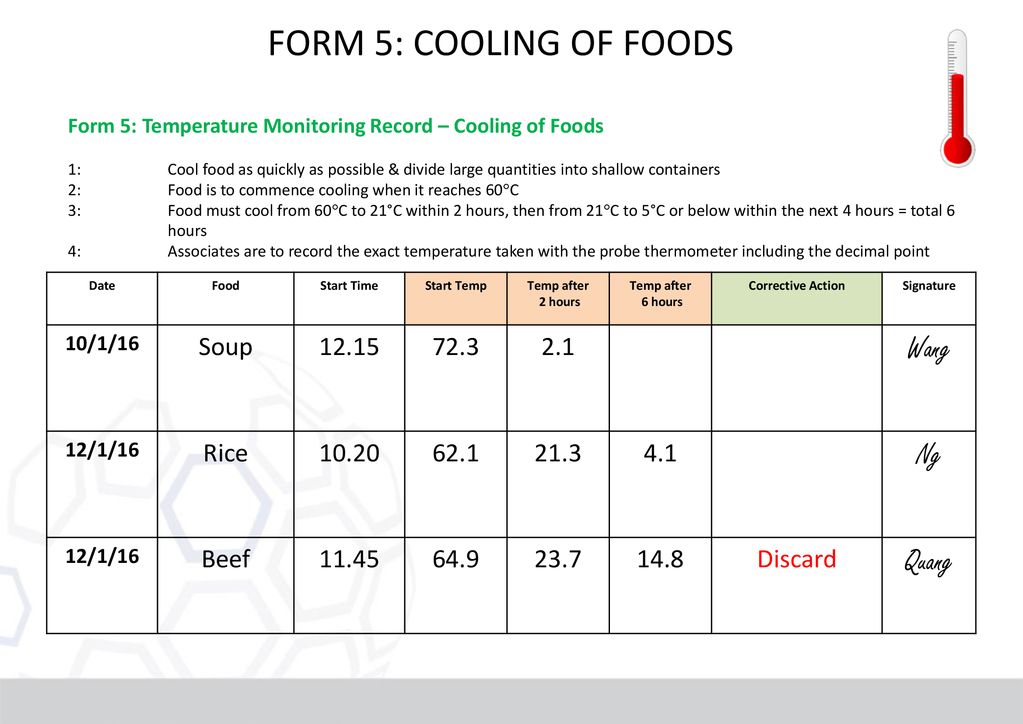

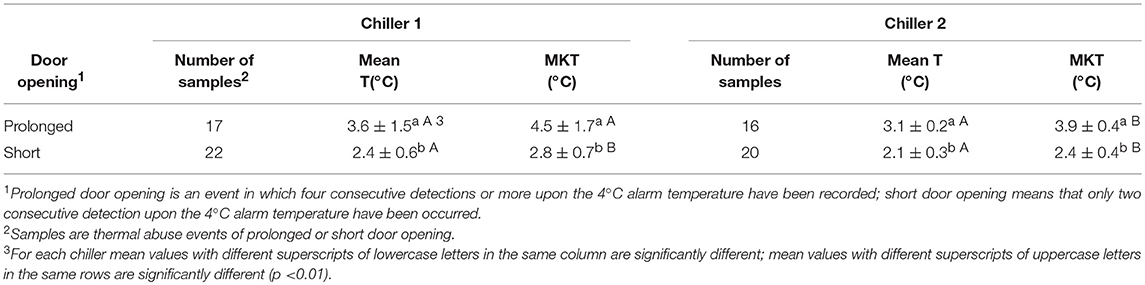

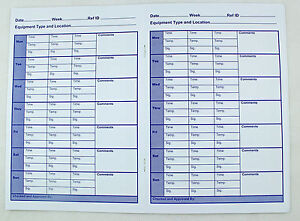

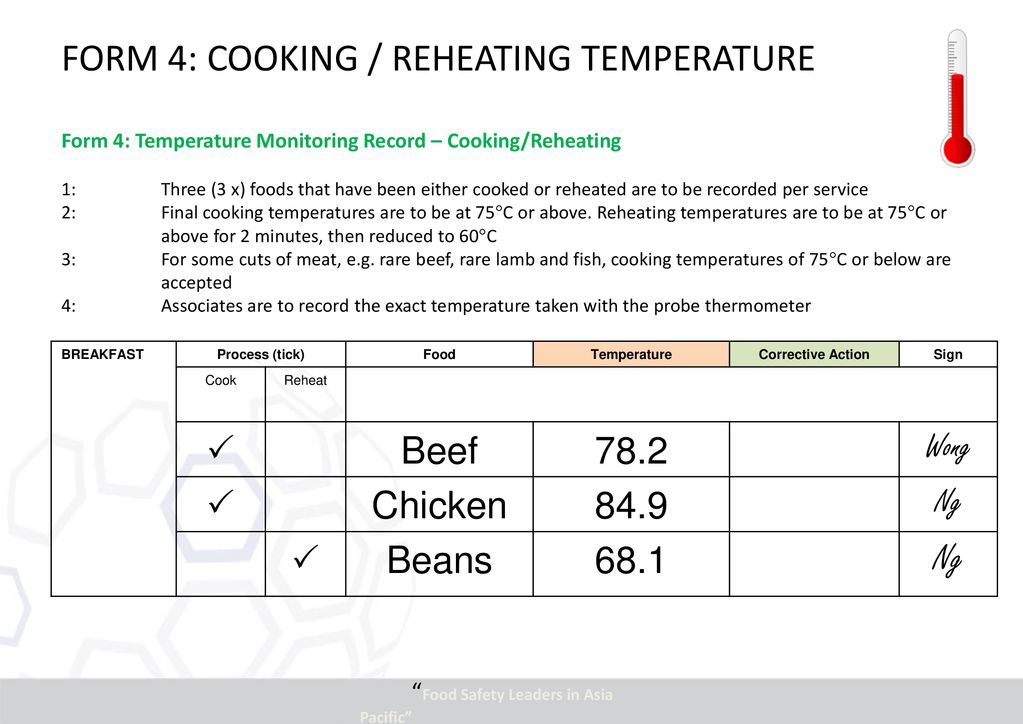

Blast chiller temperature log. 6 Place the food in a blast chiller 7 A combination of the above NOTE Regardless of the cooling method(s) used, monitor cooling temperatures to make sure that the cooling process is completed Recommend using time/temperature log sheet. Blast chillers are specifically designed to cool down bulk quantities of food quickly and effectively in a temperature controlled environment This ensures that food is not left out in unsanitary conditions unnecessarily and doesn’t compromise other chilled foods already in refrigeration. Keeping a temperature log sheet is crucial for ensuring that your commercial fridges and freezers consistently run at safe temperatures It’s an essential part of your HACCP process, which helps you to demonstrate due diligence to your local authority and protect your customers from harmful food.

Blast chiller definition 1 a piece of equipment that cools food very quickly, used for example in restaurant kitchens 2 Learn more. Cooling food temperature log keep this record for health department inspections cooling start temperature starts at 135f date your initials food item cooling method used time food is at 135 f temp @ 2 hours temp @ 6 hours corrective action (if applies) use a clean, sanitized metal probe food thermometerc. Blast Chiller the food does not reach the required temperature;.

Blast chiller has ice present in the cavity. Chiller maintenance is the process of regularly inspecting commercial or industrial chillers to extend equipment life and maintain optimum efficiency While chiller maintenance vary per type of chiller—reciprocating, centrifugal, screw, and scroll—preventive chiller maintenance should also be carried out. Temperature on HACCP temperature log NOW COVER ALL PANS, LABEL PANS WITH DATE AND NAME OF PRODUCT If a blast chiller is an option, the procedures above may not apply;.

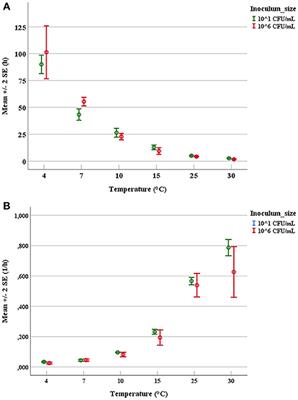

Which is the air temperature I need to consider at the blast chiller inlet ?. The blast chilling cycles are the main functions of the temperature blast chiller, and can be divided into two categories Cooling cycles and freezing cycles A cooling cycle significantly reduces the time the food remains within the critical temperature range (50ºF to 149ºF) where there is a high probability of bacterial growth. Blast chiller has ice present in the cavity.

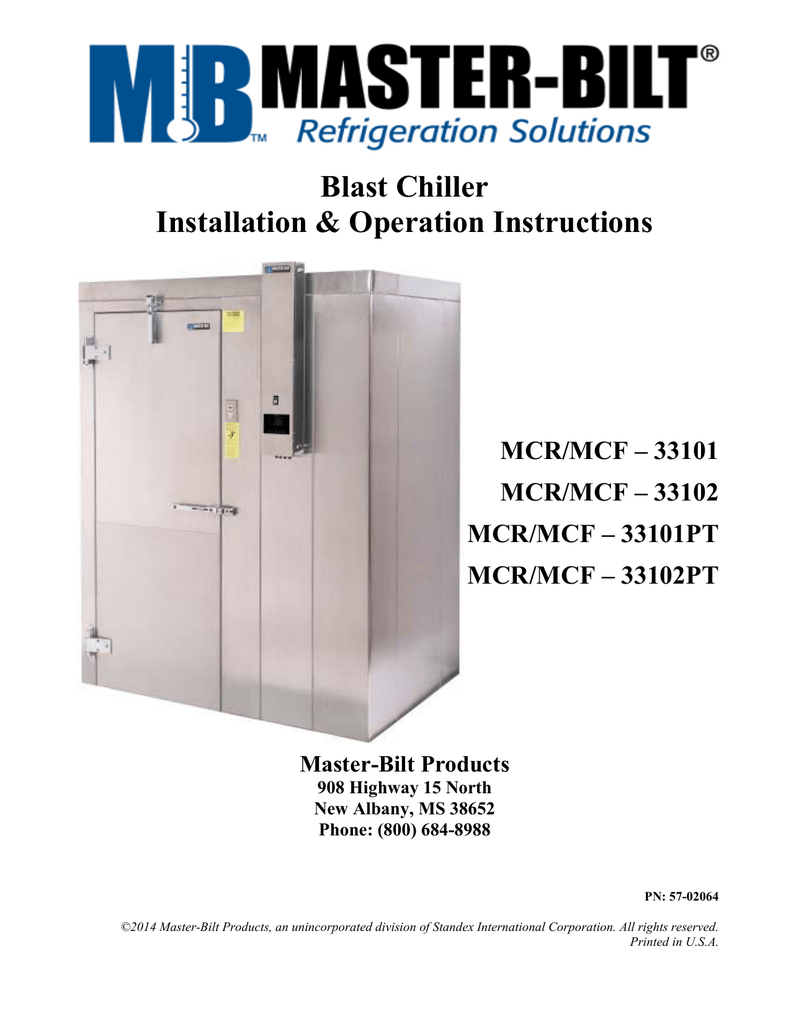

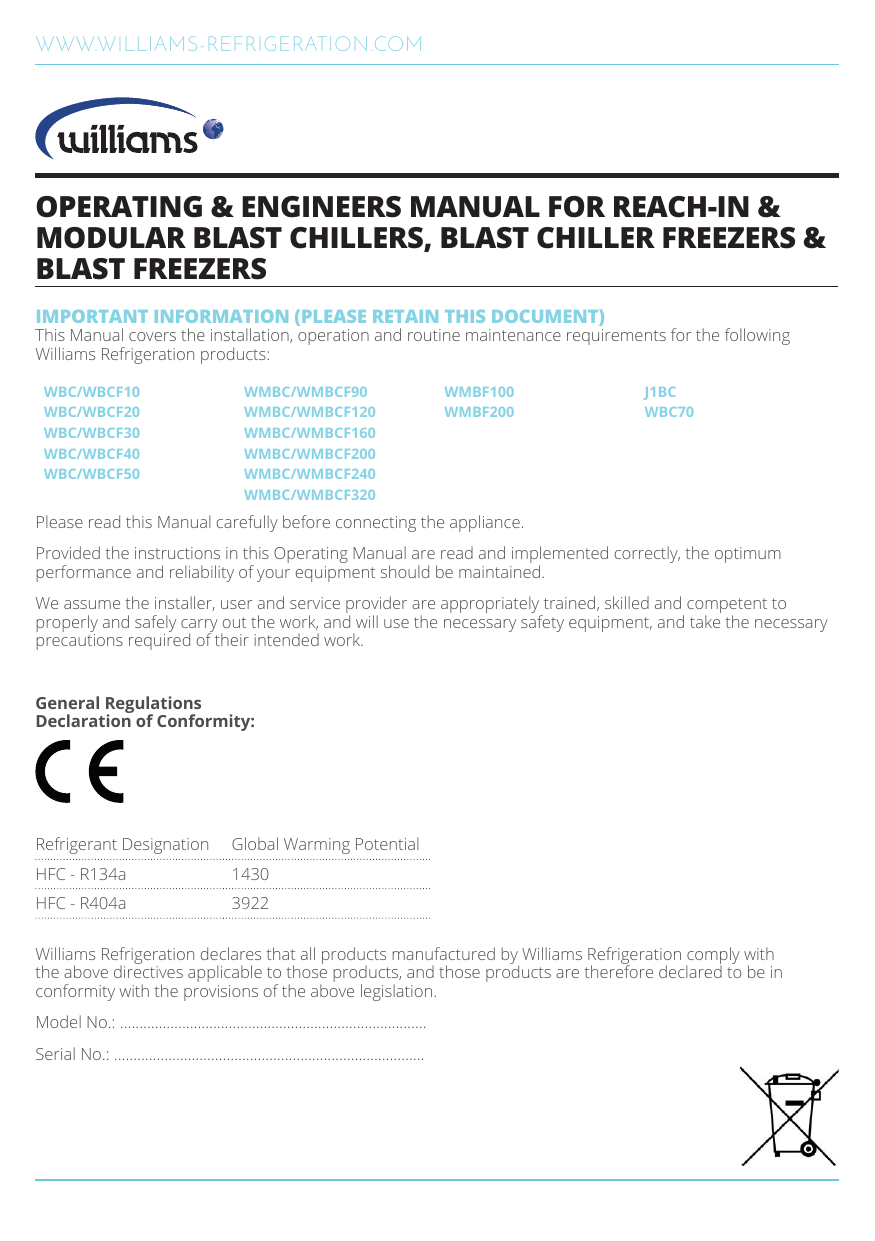

Follow the manufacture guidelines to ensure proper cooling standard is achieved and recorded appropriately. Foster XR 10 Xtra Blast Chiller The Xtra by Foster XR 10 Blast Chiller offers affordable and reliable blast chilling, giving customers a blast chilling solution perfect for kitchens that don’t have the space or requirement for large scale chilling A simple to use controller and temperature probe make this a quality solution. Rel 14 7 1 INTRODUCTION 11 Main features Blast Chiller is a complete range of controllers and user term inals for managing the blast chilling, blast freezing and conservation of foodstuffs, in compliance with the relevant standards in.

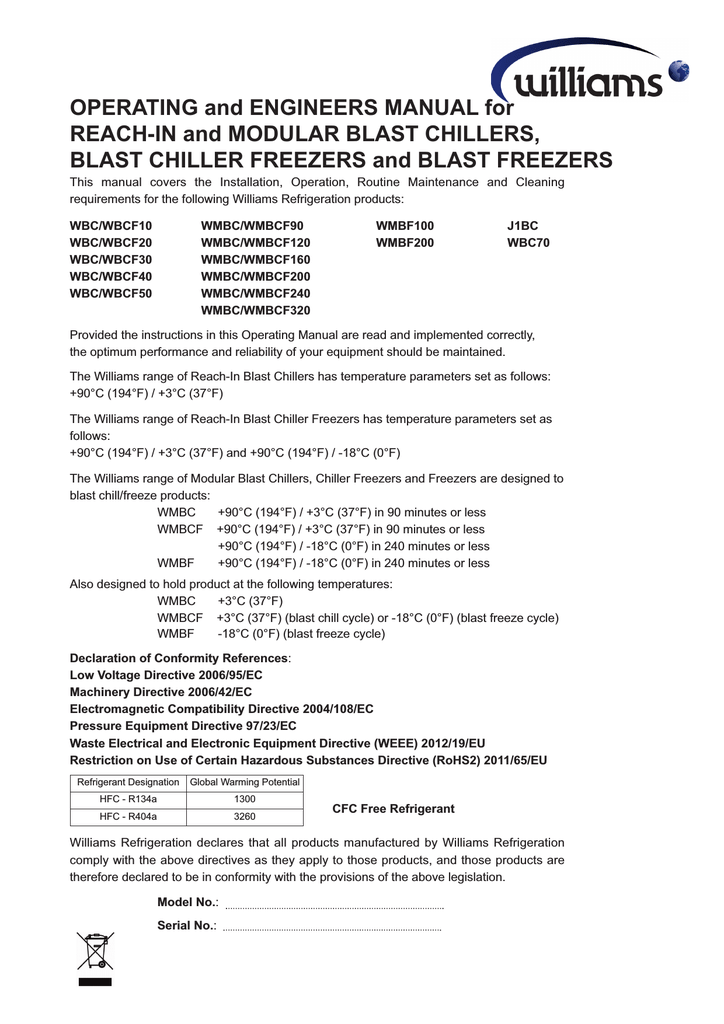

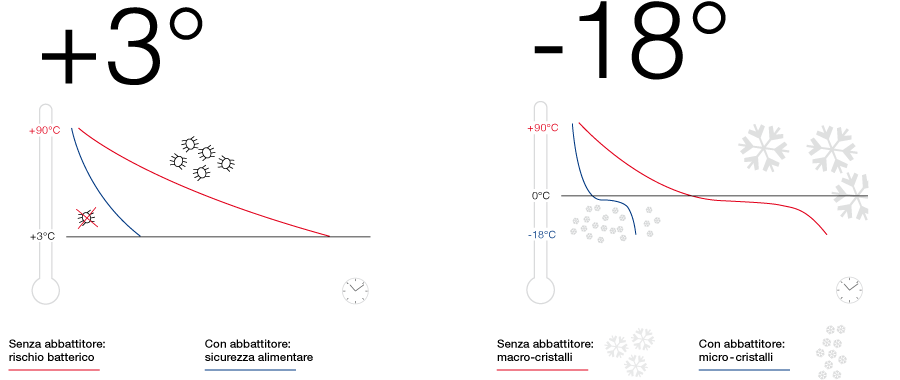

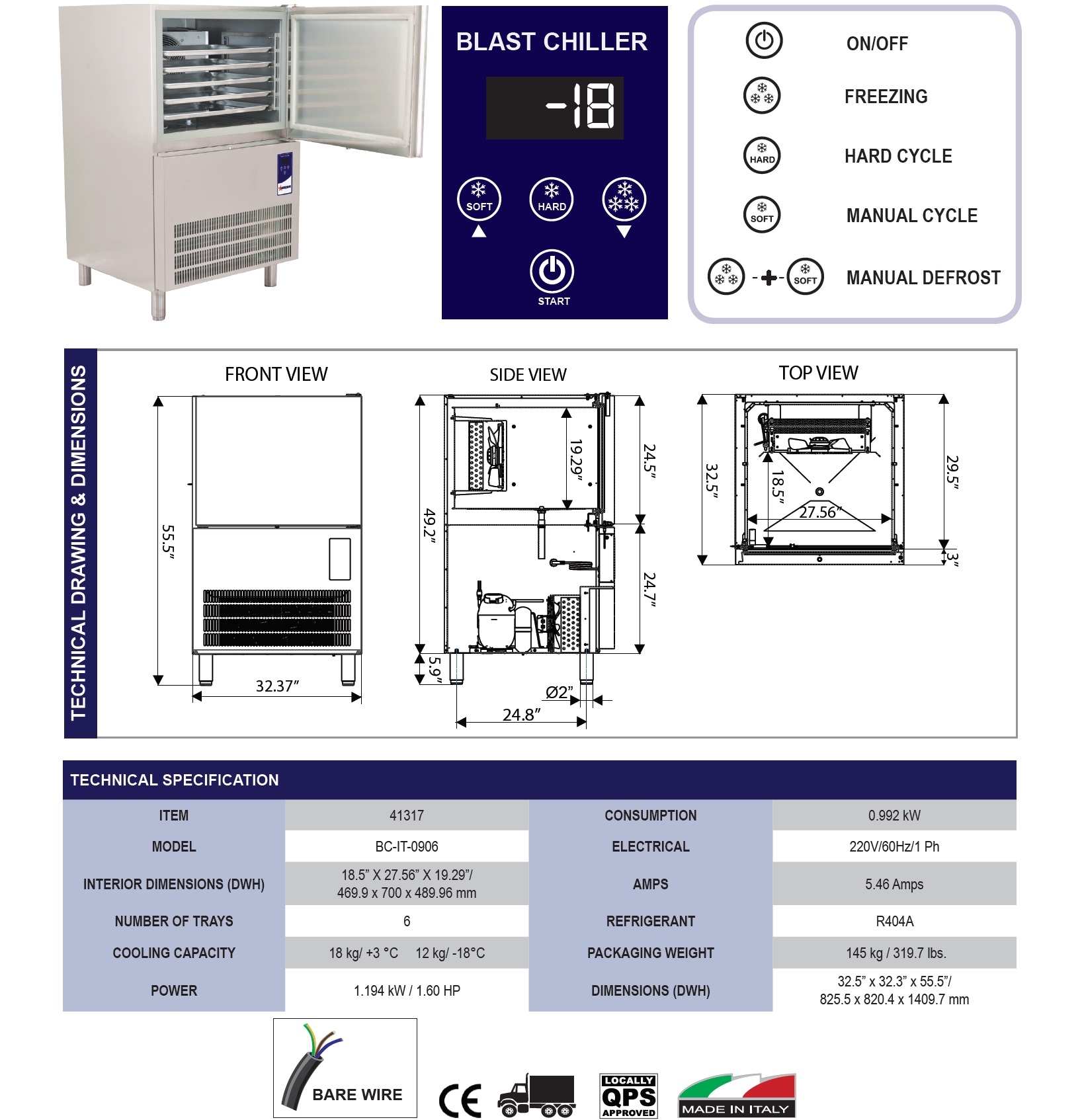

The Williams range fo ReachIn Blast Chiller Freezers has temperature parameters set as follows 90°C (194°F) / 3°C (37°F) and 90°C (194°F) / 18°C (0°F) The Williams range of Modular Blast Chillers, Chiller Freezers and Freezers are designed to blast chill freeze. The benefits of using a Blast Chiller / Freezer As a Blast Chiller / Freezer is specifically designed to quickly and efficiently reduce the temperature of hot and warm food, the refrigeration system will often consume more power than normal commercial refrigeration This can be off putting for those who are energy and cost conscious. Applies to Blast Chiller;.

Applies to Blast Chiller;. I deem in this case the huge temperature difference will calculate a very small coil Is it the final temperature I need to have in the room in order to get the 4F in the product ?. Blast chiller excessive formation of water at the bottom of the cavity;.

The washing cycle is shorter / longer than indicated on the display;. The Randell BC5 Blast Chiller will quickly and safely cool cooked foods from a temperature of 140 castlefoodequipment@aolcom Call or Text (210) Log In 1405 N Flores St San Antonio, TX 712 Home Shop Contact FAQ More 0 The Randell BC5 Blast Chiller will quickly and safely cool cooked foods from a temperature of 140. A blast chiller quickly decreases the temperature of food, helping to prevent the growth of unwanted bacteria This ensures food can be safely stored in a refrigerator then consumed at a later time Carrying a large selection of blast chillers that vary in size and style, we offer a specific unit for every type of foodservice.

6 Place the food in a blast chiller 7 A combination of the above NOTE Regardless of the cooling method(s) used, monitor cooling temperatures to make sure that the cooling process is completed Recommend using time/temperature log sheet. Resolution 1 Check that the food sensor is positioned in the product core 2 Only use timed or assisted programs and call the support service for replacement Cause Food sensor inserted incorrectly;. Use rapidcooling equipment (eg a blast chiller) stir liquid foods such as gravy often, using a clean and sanitised utensil;.

Rel 14 7 1 INTRODUCTION 11 Main features Blast Chiller is a complete range of controllers and user term inals for managing the blast chilling, blast freezing and conservation of foodstuffs, in compliance with the relevant standards in. Resolution 1 Check the program and food distribution inside the cavity 2 Check for air circulation obstructions 3 Reduce food thicknesses 4 Remove the cover or lid Cause Incorrect setting of the cooling cycle;. Resolution 1 Check the program and food distribution inside the cavity 2 Check for air circulation obstructions 3 Reduce food thicknesses 4 Remove the cover or lid Cause Incorrect setting of the cooling cycle;.

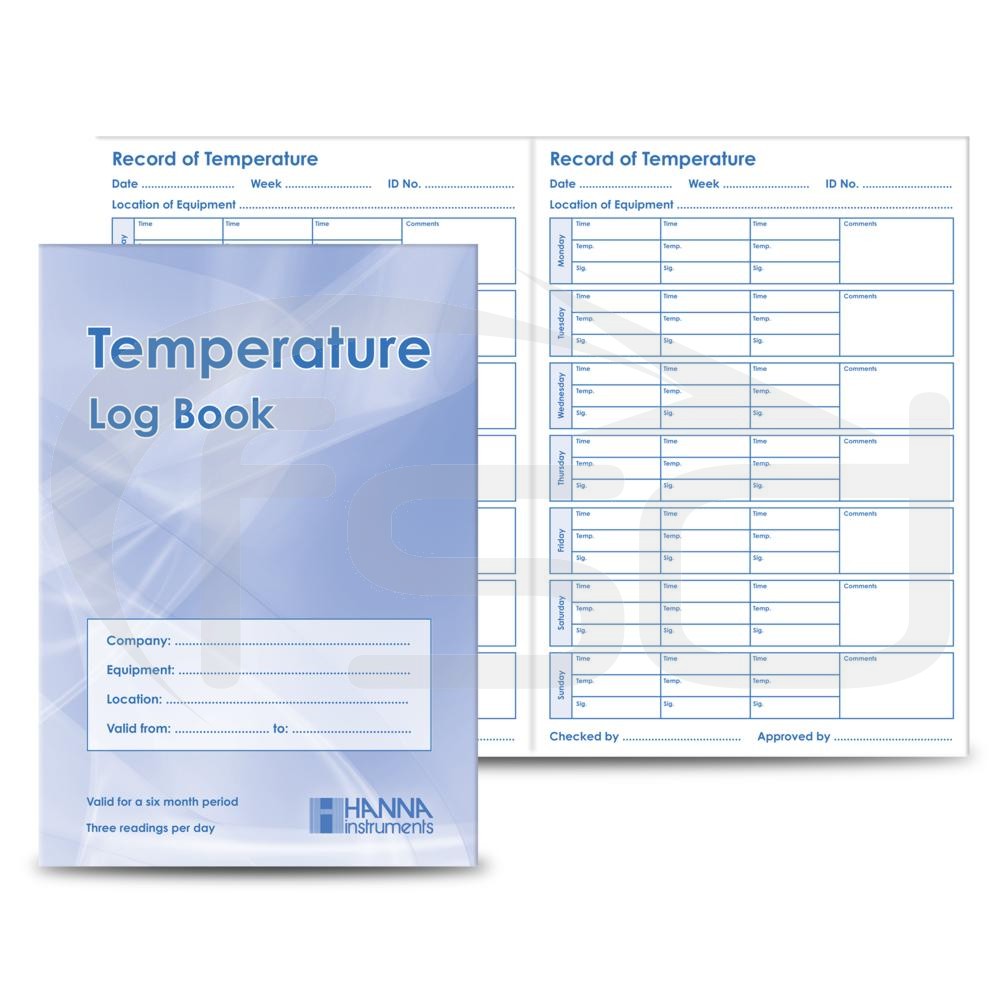

Keep a log of all the critical temperatures in your kitchen with this temperature record book from Hygiplas Produced with temperature, time and name columns, the log book helps you accurately record temperature checks to ensure your kitchen is hygienic and running according to regulations Featuring enough pages for six months' worth of records, the book lasts longer to save you money on. Equipped Blast Chiller Models 50 lb Capacity Undercounter Models 100 lb Capacity ReachIn Models 0 lb Capacity RollIn & RollThru ModelsNOTICEThis Manual is prepared for the use of trained Authorized Traulsen Service Agents and should not be used by those not properly qualified. Brightster Co Ltd is manufacturing monitoring and recording products for restaurant, central kitchen, semiindustrial and industrial kitchen to respond to Quality System such as CCP (Critical Control Point), HACCP, ISO standards.

• Make sure the cooling process starts at 135 degrees F and the second hour is at 70 degrees F or below If not, a corrective action should be recorded such as the product was properly reheated or. DXDBC45 Reachin Blast Chiller 295" × 25" × 355" / 749 × 718 × 902 cm 8v, 60 Hz, core temperature from 160°F to below 40°F • 240 minutes to bring your food temperature from temperature log • Ultraviolet light to sterilize the metal surfaces within the cabinet. Many modern blast chillers now exceed this requirement and can safely blastchill from a starting temperature of 90°C within the same time frame Keeping records of foods, their temperatures and the time it takes to chill or freeze them is an important part of HACCP a process made easier using a blast chiller, according to manufacturers.

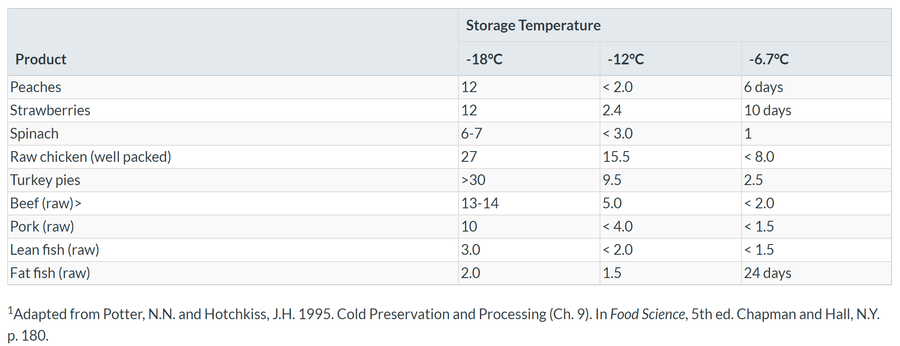

DXDBC45 Reachin Blast Chiller 295" × 25" × 355" / 749 × 718 × 902 cm 8v, 60 Hz, core temperature from 160°F to below 40°F • 240 minutes to bring your food temperature from temperature log • Ultraviolet light to sterilize the metal surfaces within the cabinet. Whatever the type of blast chiller you use, it should be capable of chilling the food between 33°F and 38°F within 2 to 4 hours of placing the hot food in the blast chiller and commencing the blast chill cycle This is not only to ensure safety, but also preserves the appearance, texture, flavor and nutritional value of the food. Blast chillers can keep your food between 0°C and 5°C, which is the recommended safe storage range Not only does a commercial blast chiller prevent the risk of foodborne illness in fish, meat, and dairy, but it also increases the shelf life of your prepared foods.

Not only do Blast Chillers ensure that the foods are not at risk of bacteria proliferation, they also prolong the life of products and reducing waste The temperature range between 65°C and 10°C provides the ideal conditions for bacterial growth, which is precisely what happens when we let cooked products cool at room temperature The longer the exposure of food to risky temperatures, the faster the growth of bacteria. Applies to Blast Chiller;. As soon as the desired temperature is reached, the blast chiller will maintain the set temperature, which depending on the food type can be set to 3 degrees Celsius or minus 18 degrees Celcius In this way, bacterial growth is inhibited and the food retains its taste and quality.

7 TRAULSEN RBC50, RBC100 & RBC0 BLAST CHILLER TRAINING GUIDE PROBLEM Upon starting a chill cycle, probe temp(s) displayed appear cooler than expected (ie cooked temperature) a Product temp within cooked batches vary Verify actual product temp with thermometer (using same probed piece) b Probe placed incorrectly. Applies to Blast Chiller;. In this my concern is to over dimension the coil in this second case.

Breed by Wyeast Farms Here you can find all info about Blast Chiller from Wyeast FarmsIf you are searching for information about Blast Chiller from Wyeast Farms, check out our Basic Infos or Lineage / Genealogy for this cannabis variety here at this page and follow the links to get even more information If you have any personal experiences with growing or consuming this cannabis variety. Use water or ice water baths;. The food sensor is damaged.

Chilling foods in a blast chiller is the preferred method spread the food out on shallow, metal trays and ensure the door is not opened unnecessarily during cooling A blast chiller should be able to reduce the temperature below 5°C within 90 minutes Highrisk foods must be cooled as rapidly as possible. The goal of a blast chiller is to chill foods at a rapid rate They can typically bring the temperature of foods down from 160 degrees to 41 degrees Fahrenheit or less in about 90 minutes This is dependent on the temperature of the food, blast chiller setting, and whether you are freezing your food or simply cooling it Blast Chilling Benefits. Keeping a temperature log sheet is crucial for ensuring that your commercial fridges and freezers consistently run at safe temperatures It’s an essential part of your HACCP process, which helps you to demonstrate due diligence to your local authority and protect your customers from harmful food.

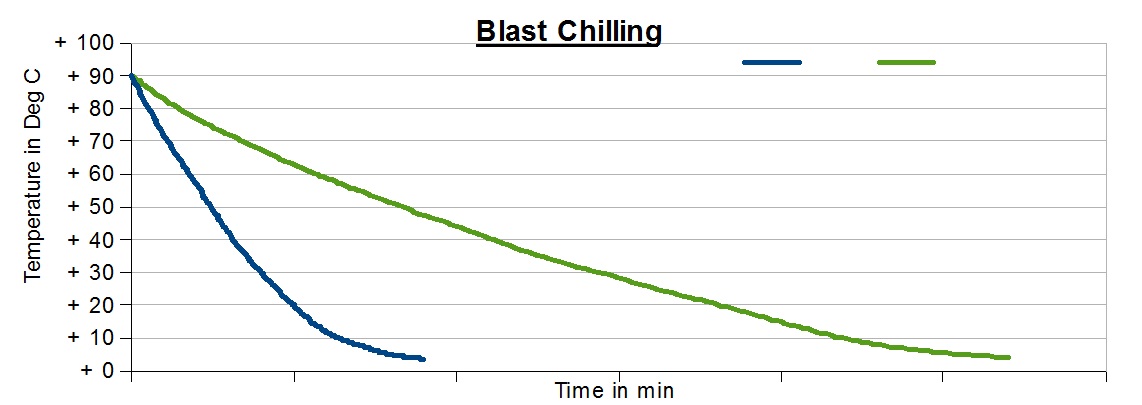

BLAST CHILLERS core temperature chamber air temperature Blast chillers are able to reduce the temperature of a food product from 70°C to 3°C at core within 90’ and to store the product at 0°C/5°C according to the storage cycle M A X 5 D A Y S core temperature chamber air temperature 70°C C 2°C less than 90’. Is it 104F ?. The PM sensor value is very high and my air purifier increases the air speed all of a sudden.

" Blast chilling of foods must be performed in a way that the core temperature does not remain between 63 ° C and 10 ° C values for more than two hours An exception is possible (Article 5) if the risk analysis shows that a lowerblast chilling time is still sufficient to ensure food safety. General characteristics Blast Chiller is CARELs' complete range of controllers and user terminals, including top of the range model with large graphic display to satisfy the needs of even the most demanding users looking for innovative & energy effi cient solutionsBlast Chiller is based on the pCO series programmable platform and features a graphic interface (pGD1 series) offering a simple. Blast chilling is a method of cooling food quickly to a low temperature that is relatively safe from bacterial growth Bacteria multiply fastest between 8 °C (46 °F) and 68 °C (154 °F) By reducing the temperature of cooked food from 70 °C (158 °F) to 3 °C (37 °F) or below within 90 minutes, the food is rendered safe for storage and later consumption.

7 TRAULSEN RBC50, RBC100 & RBC0 BLAST CHILLER TRAINING GUIDE PROBLEM Upon starting a chill cycle, probe temp(s) displayed appear cooler than expected (ie cooked temperature) a Product temp within cooked batches vary Verify actual product temp with thermometer (using same probed piece) b Probe placed incorrectly. Blast chillers are specifically designed to cool down bulk quantities of food quickly and effectively in a temperature controlled environment This ensures that food is not left out in unsanitary conditions unnecessarily and doesn’t compromise other chilled foods already in refrigeration. Blast Chiller the food does not reach the required temperature;.

Blast chillers remove the heat from food, bringing temperatures down from 160 degrees F to 38 degrees F in 90 minutes or less This process reduces the possibility of bacterial growth Foodservice operators use blast chillers to cool food prior to storing By halting the cooking cycle, blast. Blast Chiller by Noble Farms OR Remember me for 30 days I confirm that this is not a shared device Darn!. Keeping a temperature log sheet is crucial for ensuring that your commercial fridges and freezers consistently run at safe temperatures It’s an essential part of your HACCP process, which helps you to demonstrate due diligence to your local authority and protect your customers from harmful food.

Blast chiller has ice present in the cavity;. Blast chiller excessive formation of water at the bottom of the cavity;. Equipped Blast Chiller Models 50 lb Capacity Undercounter Models 100 lb Capacity ReachIn Models 0 lb Capacity RollIn & RollThru ModelsNOTICEThis Manual is prepared for the use of trained Authorized Traulsen Service Agents and should not be used by those not properly qualified.

Recommended articles for Blast Chillers Blast Chiller the temperature indicated by the food sensor is incorrect;. Cooling Log Department of Health and Environment Larimerorg/Health Cooling Log The cooling process can take no longer than 6 hours the first 2 hours to cool the food from 135°F to 70°F and 4 additional hours to cool the food from 70°F to 41°F or below If a food does not reach 70°F within 2 hours the food must be reheated to 165°F and cooled again or discarded. Food not divided properly on the.

Check temperature with a probe thermometer Tips for heating food quickly. Blast chiller Close 15 Posted by 2 days ago Blast chiller 1/2 3 comments share save hide report % Upvoted Log in or sign up to leave a comment Log In Sign Up Sort by. 7 TRAULSEN RBC50, RBC100 & RBC0 BLAST CHILLER TRAINING GUIDE PROBLEM Upon starting a chill cycle, probe temp(s) displayed appear cooler than expected (ie cooked temperature) a Product temp within cooked batches vary Verify actual product temp with thermometer (using same probed piece) b Probe placed incorrectly.

Blast Chiller the food does not reach the required temperature;. There is really no such thing as a flash chiller well, temperature differential is just that its a matter of heat removal if the bottle or can has a lot of heat, say 100F, and it is put inside a 70 degree room, it will slowly get to 70. Blast Chiller the food does not reach the required temperature;.

The blast chiller allows the product core temperature to be reduced from 160˚F to 38˚F in 90 minutes, so that the food can be kept longer with its original texture, flavor and aesthetic qualities After blast chilling, the food can be preserved at a temperature of 38˚F for up to 5 days, after which it is reconstituted to serving temperature. Blast Chiller/Shock Freezers Blast chilling and shock freezing are the best natural systems to extend the shelf life of food Delfield blast chillers are designed to improved the quality and organization of the work in restaurants, confectioneries, bakeries and icecream shops. Food not divided properly on the.

The JOFONE Blast Chiller ensures high performance shock freezing in a small space, achieving an internal temperature of 40 in just 18 minutes Multiple Applications Techfrost Shock Freezer / Blast Chillers are indispensable in all sectors of gastronomy, pastry, gelatomaking and breadmaking, where work time and food safety standards have. Blast Chiller the food does not reach the required temperature;. The JOF23 Blast Chiller ensures high performance shock freezing in a small space, achieving an internal temperature of 40 in just 18 minutes Multiple Applications Techfrost Blast Freezer / Blast Chillers are indispensable in all sectors of gastronomy, pastry, gelatomaking and breadmaking, where work time and food safety standards have an.

Recommended articles for Blast Chillers Blast Chiller the temperature indicated by the food sensor is incorrect;. Use this general employee temperature log sheet to keep a record of employees’ temperature whenever they report in for work Log as many temperature records as needed This employee temperature log sheet recognizes 1003° F as the threshold and prompts a visual cue for 1004° F and above temperature readings Download Template. The blast chiller allows the product core temperature to be reduced from 160˚F to 38˚F in 90 minutes, so that the food can be kept longer with its original texture, flavor and aesthetic qualities After blast chilling, the food can be preserved at a temperature of 38˚F for up to 5 days, after which it is reconstituted to serving temperature.

Find Blast Chiller Parts at Parts Town with the largest instock inventory and same day shipping until 9pm ET When you log in, your account details, shipping addresses, payment info, equipment details, catalog of parts you've researched and your order history are all saved for you No need to type it all again. Food not divided properly on the. Blast chiller excessive formation of water at the bottom of the cavity;.

Blast Chiller the temperature indicated by the food sensor is incorrect;. Resolution 1 Check the program and food distribution inside the cavity 2 Check for air circulation obstructions 3 Reduce food thicknesses 4 Remove the cover or lid Cause Incorrect setting of the cooling cycle;. 7 TRAULSEN RBC50, RBC100 & RBC0 BLAST CHILLER TRAINING GUIDE PROBLEM Upon starting a chill cycle, probe temp(s) displayed appear cooler than expected (ie cooked temperature) a Product temp within cooked batches vary Verify actual product temp with thermometer (using same probed piece) b Probe placed incorrectly.

Blast Chillers Freezer March 14, 16 by ADK How Blast Chillers And Blast Freezers Work Blast chillers and blast freezers are a great addition to any food production or kitchen setup They can help extend the lifespan of food products and ingredients without detrimentally affecting the nutrients, aroma, colour, texture, flavour and safety.

Use Of Blast Freezers In Vaccine Manufacture Bioprocess Internationalbioprocess International

Electrolux Crosswise Blast Chiller Freezer 11 Tray 11 X 1 1gn Rbf101 Popular Accessories Electrolux Refrigeration Rac52 Crosswise Blast Chiller And Freezer Accessory Unavailable Features Designed Solely For Rapid Reduction In Food Temperature The

Chef Link Temperature Log Book 001cltemplog 10 18 Chef Link Hospitality Supplies

A New Scaleable Freeze Thaw Technology For Bulk Protein Solutions Shamlou 07 Biotechnology And Applied Biochemistry Wiley Online Library

Temperature Log For Refrigerator Free Download

35c Temperature Stainless Steel 304 Blast Freezer For Popsicle View Blast Freezer For Popsicle Haiyao Product Details From Foshan Haiyao Frozen Equipment Co Ltd On Alibaba Com

Safe Catering 5 Recording Forms

Are Blast Chillers And Blast Freezers Suitable For Your Business Acmefg

Cdn2 Webdamdb Com Md Zgajcmrpzwrv Jpg Pdf

Www Universalcitytexas Com Documentcenter View 22

Temperature Log Book J1 Buy Online At Nisbets

Impact Of Temperature Sampling Strategy On The Risk Of Clostridium Growth Application To Rapid Cooling Of Food In Institutional Food Service Facilities Sciencedirect

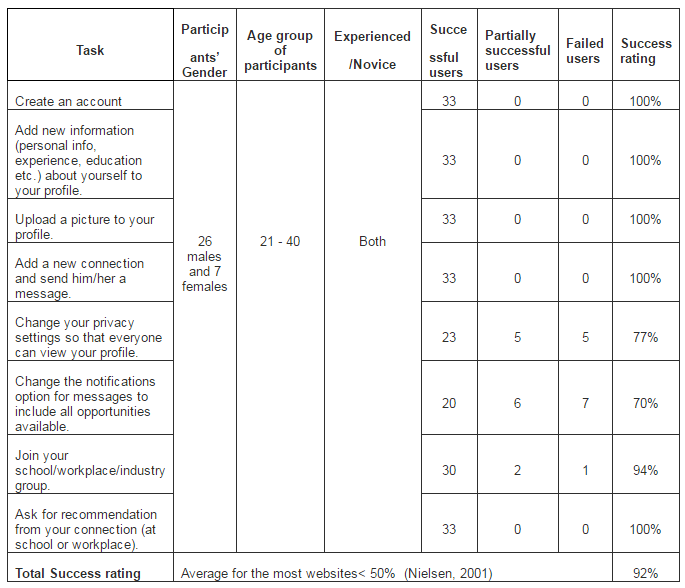

Ibima Publishing Improving Usability Of Social Networking Systems A Case Study Of Linkedin

Foster Blast Chiller Service Manual Manualzz

Chill Smart Blast Chiller Manufacturing Net

Www Larimer Org Sites Default Files Uploads 17 Lcdhe Cooling Log Pdf

Victory Blast Chiller Shock Freezer Vbcf 230 Culinary Depot

Www Sccgov Org Sites Deh Facilityinspectionreports Inspectionreport Da7nx9m6v Pdf

The In Depth Blast Chiller And Freezer Buying Guide Ffd Ltd

Time And Temperature Control Tcs Foods Full Guide Thermopro

2

Safe Catering 5 Recording Forms

Safety First Establishing The Right Food Safety Workflows Logile

Temperature Log Book J1 Next Day Catering

2 X Appliance Temperature Monitoring Record Book Fridge Freezer Chiller Log For Sale Ebay

Temperature Log Book

As1105n 5 Tray Temperature Blast Chiller

Temperature Log Book Record Food Hygiene Guide Catering Fridge Freezer 4 75 Picclick Uk

2

Beverage Air Com Wp Content Uploads 17 02 Pdf

Hse Guidelines For Maintaining The Vaccine Cold Chain Including Maintenance Of Vaccine Fridges And Management Of Vaccines Pdf Free Download

Safebites Time And Temperature Control How To S Foodhandler

Http Www Wakegov Com Food Healthinspections Rules Documents Enforcement manual Cold hold rcp Pdf

Mcr Series Blast Chiller Manual Manualzz

Safe Food Hygiene Standards Ppt Download

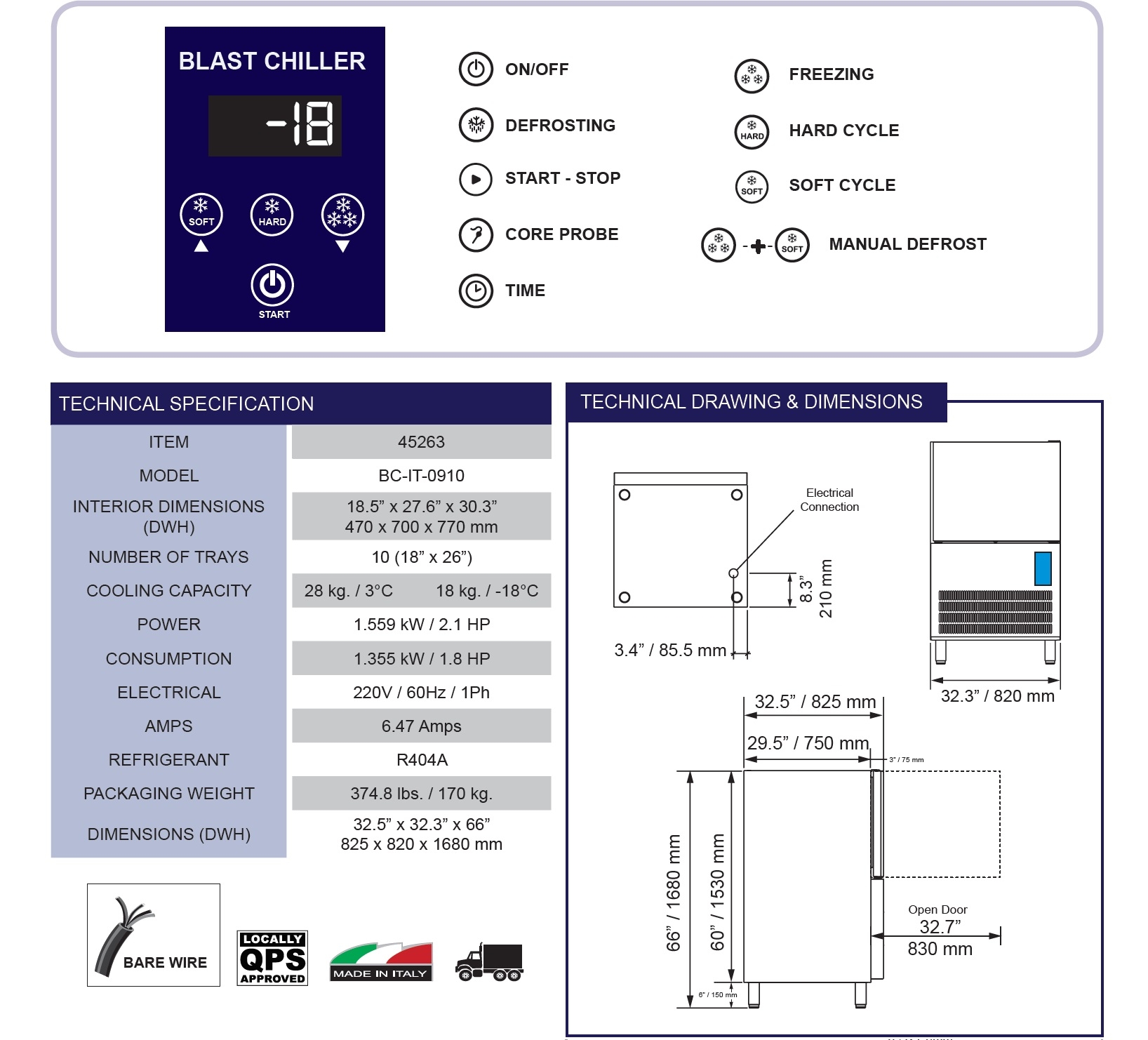

Omcan 2 1 Hp Blast Chiller Fits 10 Trays

Mehen Hot Sale Commercial Large Capacity Blast Chiller Freezer For Ice Cream Buy Blast Chiller Freezer Blast Chiller Freezer For Ice Cream Commercial Blast Chiller Freezer Product On Alibaba Com

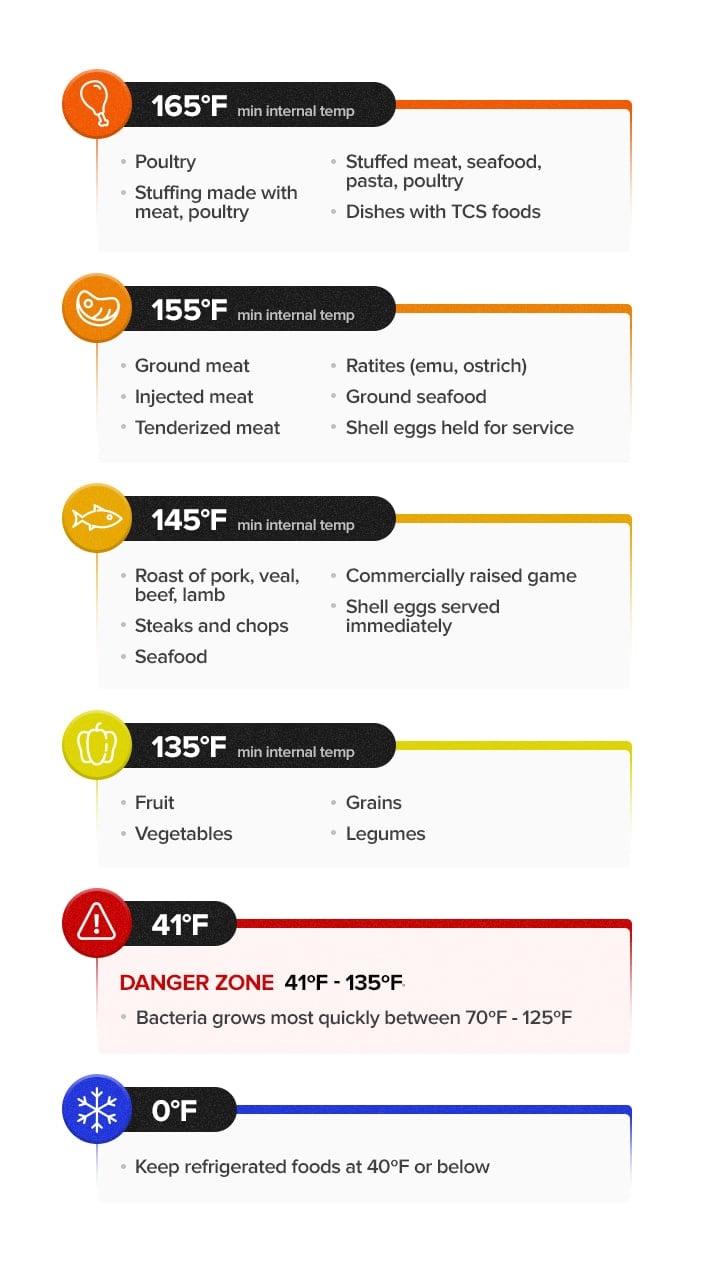

Temperature Danger Zone Safe Food Temperatures

Mod Cab Count Combined 1st Half f51 Blast Chiller Service Manual

Step In Blast Chillers Freezerve

Safebites Time And Temperature Control How To S Foodhandler

Deluxe Blast Chiller Shock Freezer Quick Cooler 3 X 1 1 Gn Maxima Holland

Buy Chiller Freezer Temperature Log X10 In Cheap Price On M Alibaba Com

Blast Masters Latest Blast Chilling Solutions Provide Operators With A Rapid Route To Menu Maximisation

Blast Chiller 10 Trays 60x40cm Gn1 1 With Stainless Steel Structure

Blast Freezer Temperature Flash Freeze

Blast Chiller Operating Manual Manualzz

Pdf Processing Storage And Quality Of Cook Chill Or Cook Freeze Foods

Http Www Italiangelato Com Au Pdfs Manuals Hiber User Manuals Um Hiber Blast Freezers Gelato Pastry Pdf

3

Pdf Cooling Rate Of Chili Using Refrigerator Blast Chiller And Chill Stick Methods

Polar Dn494 Specification Sheet Manualzz

Hygiplas S595 Special Offer Hygiplas Multistem Thermometer And Temperature Log Book S595 Hand Held Electronic Probes

A New Scaleable Freeze Thaw Technology For Bulk Protein Solutions Shamlou 07 Biotechnology And Applied Biochemistry Wiley Online Library

Hanna Temperature Log Book Thermometer Superstore

Blast Chiller Shock Freezer 3 X 1 1 Gn Model A Saro

Frontiers Determination Of Temperature Dependent Growth Parameters In Psychrotrophic Pathogen Bacteria And Tentative Use Of Mean Kinetic Temperature For The Microbiological Control Of Food Microbiology

Www Crionovo Be Nl System Files Downloads Handleiding Friginox Nt Fx Emploi Touch Screen En 1014 Pdf

Q Tbn And9gcqv Xzokc1x2cj8cjaq3io546ofzmeuwsdybe Uhi Ux2hf5xs6 Usqp Cau

Www Immunize Org Catg D P3037c Pdf

Climate Emerson Com Documents New Blast Chiller Application En Gb Pdf

Climate Emerson Com Documents New Blast Chiller Application En Gb Pdf

Www Loraincountyhealth Com Files Environmental health Cooling food log and requirements ddk 281 29 Pdf

Mod Cab Count Combined 1st Half f51 Blast Chiller Service Manual

Tt04 Temperature Data Transceiver User Manual Guide Katchall Technology Group

Cateringbase For All Your Catering Equipment Needs Cateringbase Ltd

Ed Sc Gov Districts Schools Nutrition Wellness And Food Safety Food Safety Hazard Analysis Critical Control Point Haccp Binder 2 Haccp Plan 2 6 Monitoring And Recordkeeping

2

Electrolux Air O Chill Blast Chiller Freezer Tray 10 X 2 1gn

Knowledge Base

Frontiers Determination Of Temperature Dependent Growth Parameters In Psychrotrophic Pathogen Bacteria And Tentative Use Of Mean Kinetic Temperature For The Microbiological Control Of Food Microbiology

15 Trays Blast Chiller And Freezer Gti 60 Buy Blast Blast Chiller Blast Freezer Product On Alibaba Com

Knowledge Base

10x Temperature Log Book Six Month Record Record Food Hygiene Guide Catering Log Ebay

Llufb Llu Lv Conference Foodbalt 11 Foodbalt Proceedings 11 4 8 Pdf

Virtus Group Gmbh Catalog Bkz0040 Pass Through Blast Chiller For Remote Cooling x Gn 1 1 90 C 18 C

Tt04 Temperature Data Transceiver User Manual Guide Katchall Technology Group

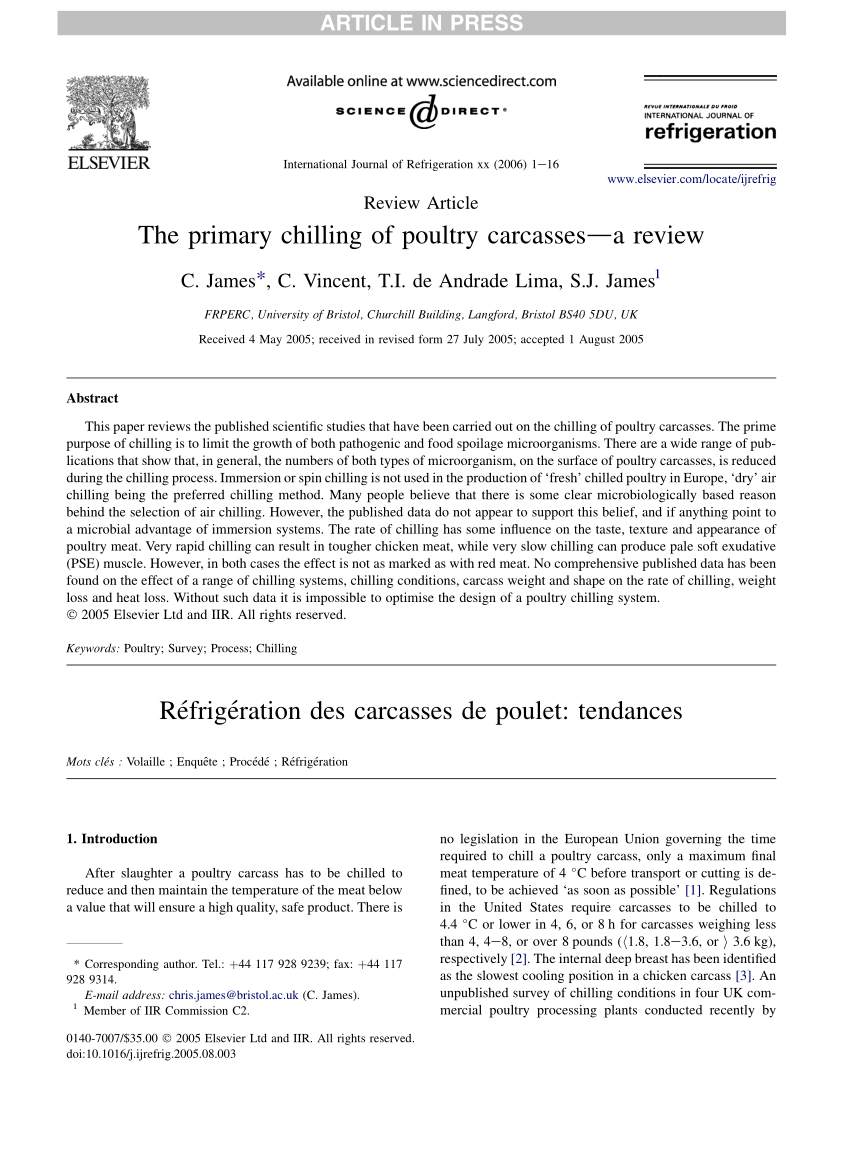

Pdf The Primary Chilling Of Poultry Carcasses A Review

Temperature Log Sheets For Busy Kitchens Free Templates

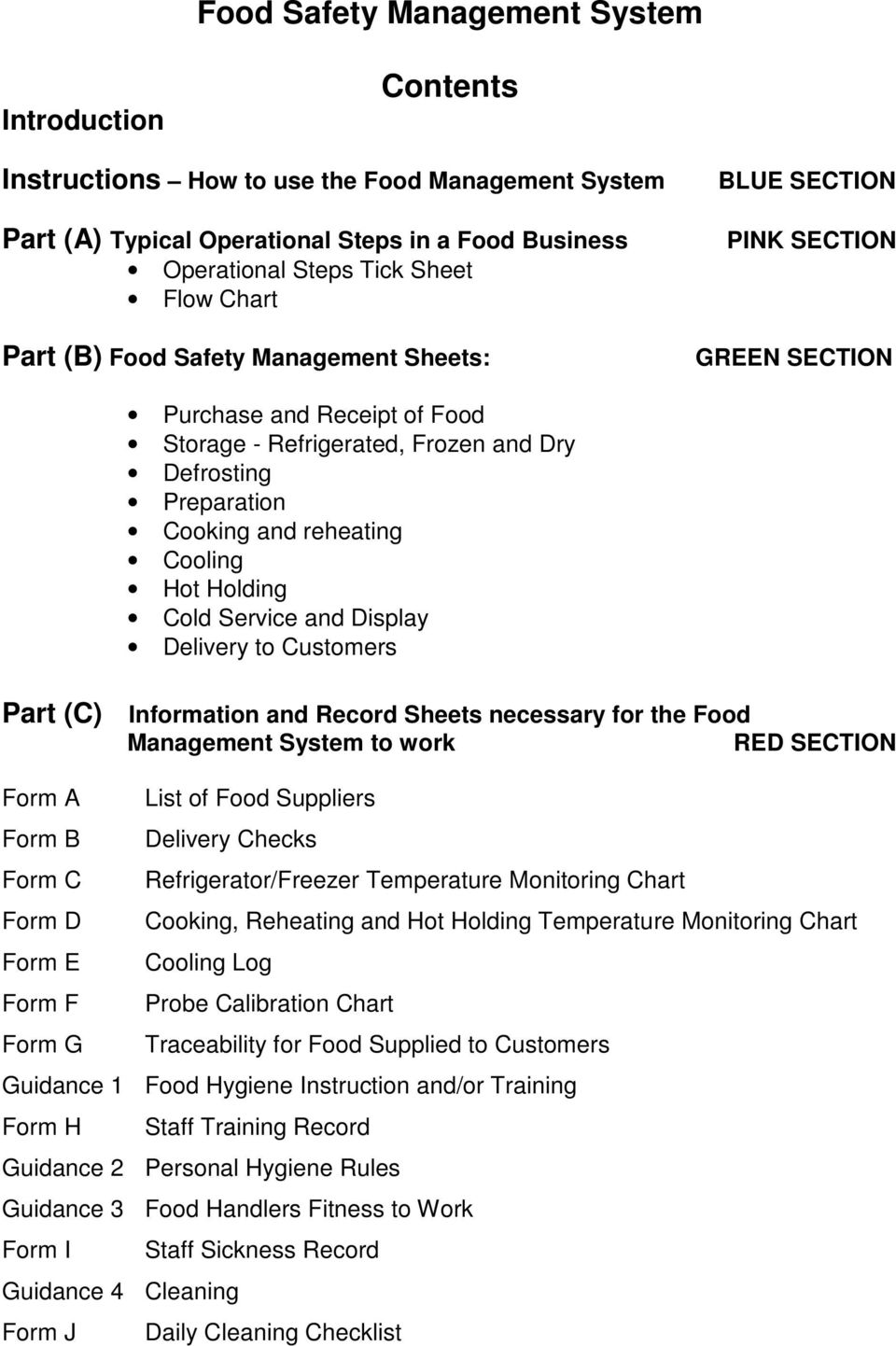

Food Safety Management System For Pdf Free Download

Www Weldgov Com Userfiles Servers Server 6 File Departments Health and environment Enrivonmental health Food safety For regulated facilities About Cooling log Pdf

Www Hsdl Org View Did

Blast Chiller Shock Freezer Model Ursus 10 Saro

Course Fnh0 Lessons Lesson 07 Ubc Wiki

Www Albertahealthservices Ca Assets Wf Eph Wf Eh Serving Safer Food Alberta Guidebook Pdf

Deluxe Blast Chiller Shock Freezer Quick Cooler 3 X 2 3 Gn Maxima Holland

Electronic Blast Chiller And Freezer Mod Alexander 2 3 Air Cooled Rack Capacity N 2 X Gn 2 3 Cm 35 4 X 32 5 Core Probe Chilling 70 3 Kg 8 Freezing 70 18 Kg 3 Dimensions Cm L 68 X D 54 X H 52 Ec Standards Allforfood

Built In Blast Chiller Life W60 Life Collection By Coldline

2 X Appliance Temperature Monitoring Record Book Fridge Freezer Chiller Log For Sale Ebay

Pdf Cooling Meat Products In Foodservice Time Temperature And Growth Of Clostridium Perfringens Atcc 103

Blast Chillers Jolyice

Safe Food Hygiene Standards Ppt Download

Hazardous Foods Temperature Management The Importance Of Blast Chillers Euroquip

Blast Chiller Operating Manual Manualzz

Cooling And Reheating Food

Omcan 1 60 Hp Blast Chiller Fits 6 Trays

Servallcatering Com Wp Content Uploads 16 04 5u 10u 14u User Manual Pdf

Electronic Blast Chiller And Freezer Mod Alexander 5 Stu