Metal Smelting

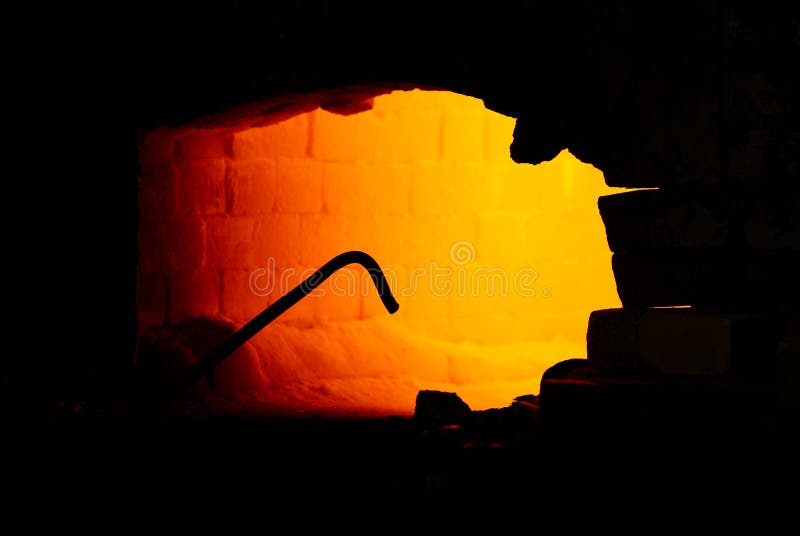

Safe Reliable Extraction Of Casting Fumes Keller Lufttechnik

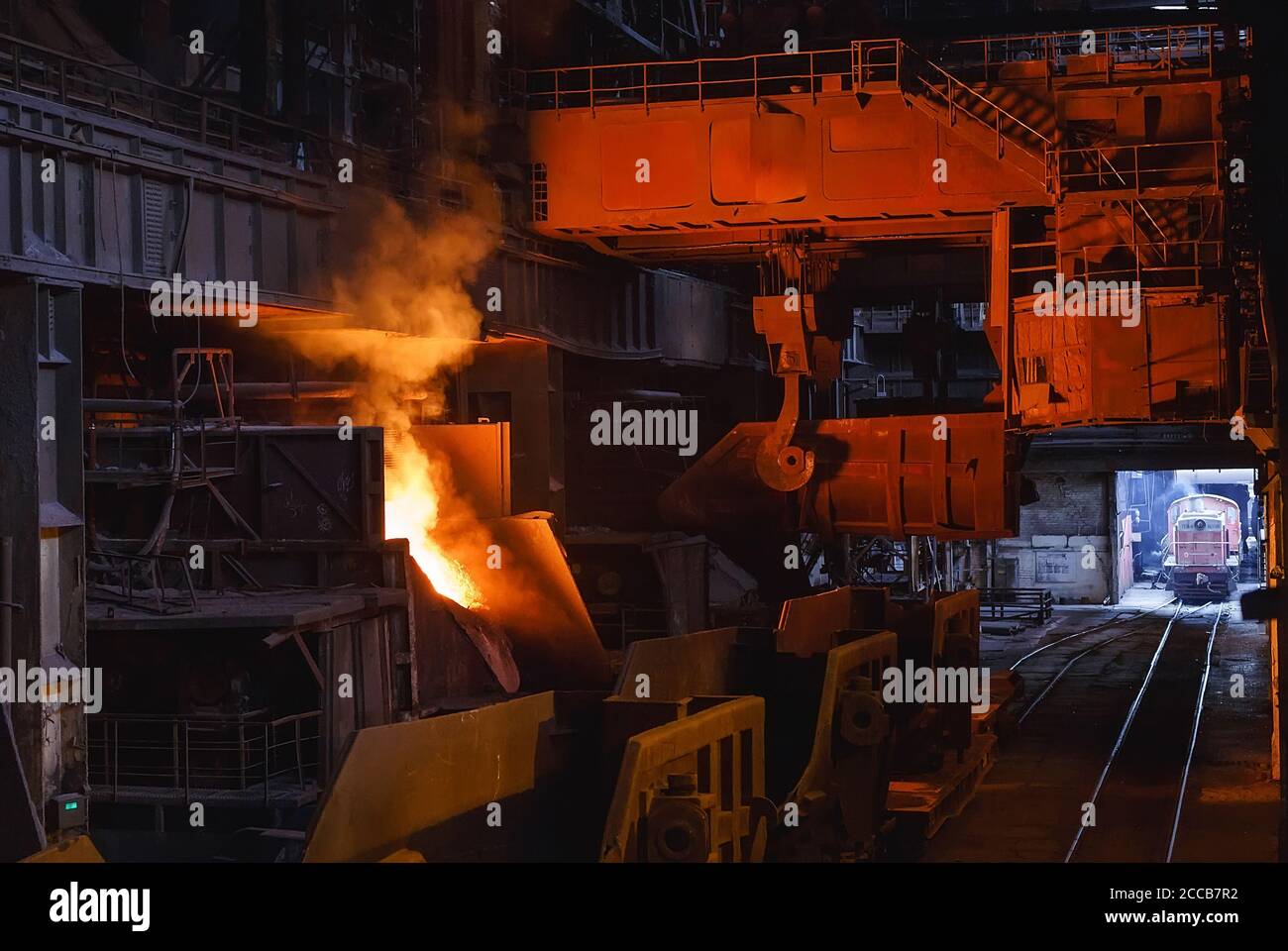

Metal Smelting Furnace In Steel Mills Stock Photo Picture And Royalty Free Image Image

What Is Smelting And Iron Ore Smelting Process Studentlesson

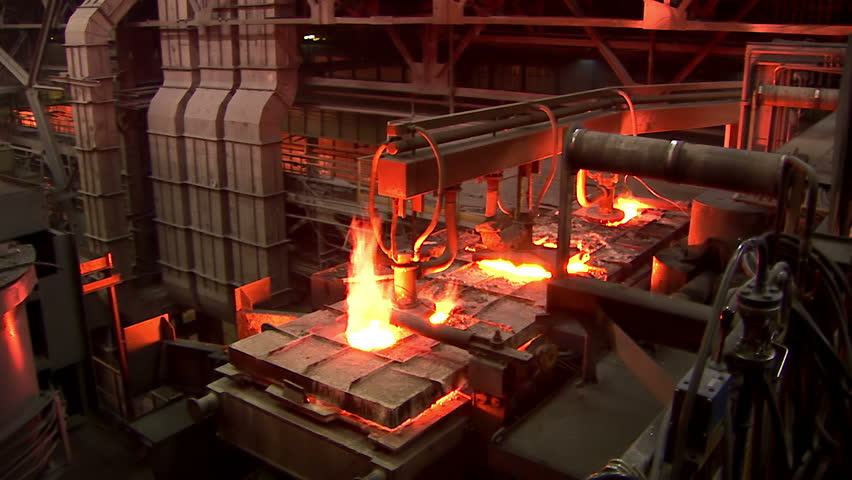

Iron And Steel Works Metal Stock Footage Video 100 Royalty Free Shutterstock

Smelting Of The Metal In The Foundry On The Factory Stock Photo Alamy

Hard Work Foundry Metal Smelting Furnace Steel Mill Molten Metal Stock Video C Videoserg

You guessed it copper.

Metal smelting. It was another 1,000 years before iron was reduced from its ores Mycenaean dagger, bronze with gold, silver, and niello, 16th century bc. A crucible is a metal container that you put inside of your furnace that holds the metal you’re melting Put the metal you want to melt inside the crucible and use a pair of fire tongs to set it in the middle of your furnace Allow the furnace to heat the crucible and melt the metal before taking it out with tongs for casting. Tech, industrial, social change;.

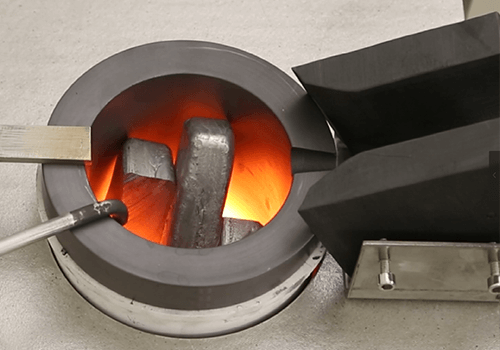

The Quick Melt Kiln model is for anyone doing precious metal treatment or melting precious metal like old and gold, silver, copper, jewellery or scrap The QM melting kiln is actually offered with 5 different sizes in reference to the crucibles Electric Metal Melting Furnace The graphite crucible size translates into kiln melting capacity being. Did you scroll all this way to get facts about metal smelting kits?. A crucible is a metal container that you put inside of your furnace that holds the metal you’re melting Put the metal you want to melt inside the crucible and use a pair of fire tongs to set it in the middle of your furnace Allow the furnace to heat the crucible and melt the metal before taking it out with tongs for casting.

Main article Ingot Dwarven Metal Ingot is a crafting material found in The Elder Scrolls V Skyrim It is used to craft and improve various weapons and armor via smithing 1 Background 2 Smithing 21 Dwarven Armor 22 Dwarven Weapons 3 Locations 4 Smelting 5 Trivia 6 Appearances Dwarven Metal Ingots were the metal of choice for the Dwemer The method of producing these ingots was known only. New tech smelting and metal tools/weaponsPottery/textiles – mass productionSocial stratification Based on control of resources, family, religious or political authority, and wealthWriting associated with growth of cities Civilization urbanism;. The metal bank can also be used while smelting and smithing at the aforementioned objects When smelting or smithing, ores and bars are taken directly from the metal bank without the need to withdraw to the inventory first However, the metal bank cannot store smithed items they have to be banked normally.

In addition to toxic emissions, lead smelting produces wastewater, solid waste, and slag heaps that may be contaminated with heavy metal Lead from these sources, as well as waste rock from lead ore mining, can often make its way into ground and surface water systems that are used for drinking, bathing, and cooking. Smelting is the process of extracting the metals from ores in the purest form It involves heat and chemicals to melt the ore and convert it into pure metals There are two requirements of the smelting process, heat treatment, and reducing agent Smelting obtains a metal at temperatures beyond the melting point from its ore. And new methods of communication Bronze tin & copper Archaeologists coined the term.

Smelting is the process in which one transforms ore (or Dwemer metal scraps) into ingots Although related to Smithing, smelting does not improve the Smithing Skill Smelters can be found in most large towns, as well as near many mine entrances. Metal smelting is the process of creating metal by heating metal ore The ore, be it iron, copper or tin, is mixed with a carbon and the mixture is heated to the point of conversion into a liquid form The liquid is then mixed with a flux, such as limestone, when metal smelting. New tech smelting and metal tools/weaponsPottery/textiles – mass productionSocial stratification Based on control of resources, family, religious or political authority, and wealthWriting associated with growth of cities Civilization urbanism;.

In the smelting process a metal that is combined with oxygen—for example, iron oxide—is heated to a high temperature, and the oxide is caused to combine with the carbon in the fuel, escaping as carbon monoxide or carbon dioxide Other impurities, collectively called gangue, are removed by adding a flux with which they combine to form a slag. Designated items for the Smelting Process according to the fuel strategy (see above) 2 Stone Input 10 Stone> 1 Brick Stone has other purposes too Split them and put every stone in here that can be smelted without further thinking 3 Ironstone Input 2 Ironstone> 1 Iron Bar Every Ironstone one time has to be smelted into an Iron Bar A large supply of Iron Stone reduces downtime. At will steel blossoms bloom in unnamed gardens, or flowerswords flash in the moonlight This fallen metal from the sky, be it a gift from the gods or a curse from the wells of night, has mysterious properties that sages and sorcerers are only beginning to understand This strange material is not as easy to work with as earthly metals, but those of esoteric skill have devised a way to smelt star metal ore, with a technique that employs brimstone and black ice, to create ingots.

Rotary Furnace Refining Pot. Bloomery forges are the oldest form of smelting iron first used thousands of years ago In early to mid 19 a group of volunteers at The Crucible in Oaklan. During smelting, when the ore is exposed to high temperatures, these impurities are separated from the molten metal and can be removed Slag is the collection of compounds that are removed In many smelting processes, oxides are introduced to control the slag chemistry, assisting in the removal of impurities and protecting the furnace.

NEO Aluminio Colombia plans to build a low carbon primary aluminum production facility in Colombia, which will be named the Green Aluminium Transformation Complex for Colombia (GALTCO) The project — which is intended to reach a capacity of 540,000 tonnes of aluminum per year — will represent the country’s first foray into aluminum smelting. And new methods of communication Bronze tin & copper Archaeologists coined the term. Utilizamos cookies para asegurar que damos la mejor experiencia al usuario en nuestro sitio web Si continúa utilizando este sitio asumiremos que está de acuerdo.

Smelting is a skill in the Smith tree Leveling up Smelting allows players to smelt different types of ores into bars, and unlocks the respective skills to improve their speed and efficiency in smelting 1 Unlocks 2 Learning 21 Crafting Recipes 22 Used in Recipes None. 1 Overview 2 Usage 3 Known Locations 4 Gallery Metal is a resource under the generic Metal type of resources All the nongeneric resources of this type are Cobalt Copper Iridium Iron Silver Tin The various resources within this type are interchangeable for crafting common items For crafting higherquality blueprints, you will need to include two or more of these named resources, but not the. Here are some important legal and environmental considerations you should take before or in the course of operating a metal melting company Location Make sure you choose a place that is not in the middle of a residential area to avoid being disrupted by the Government papers and licenses.

New tech smelting and metal tools/weaponsPottery/textiles – mass productionSocial stratification Based on control of resources, family, religious or political authority, and wealthWriting associated with growth of cities Civilization urbanism;. When smelting or smithing, ores and bars are taken directly from the metal bank without the need to withdraw to the inventory first However, the metal bank cannot store smithed items they have to be banked normally When smelting, bars are not automatically deposited into the metal bank unless smelting gauntlets are worn. Smelting is a form of extractive metallurgy to produce a metal from its ore Smelting uses heat and a chemical reducing agent to decompose the ore, driving off other elements as gasses or slag and leaving just the metal behind The reducing agent is commonly a source of carbon such as coke, charcoal, and coal.

Your trusted source for metal detectors, dredges, highbankers, drywashers, smelting, refining, assaying supplies, books, prospecting tools, and so much more AB Prospecting The Southwest's Largest Prospecting Store since 1979. In metallurgy, refining consists of purifying an impure metal It is to be distinguished from other processes such as smelting and calcining in that those two involve a chemical change to the raw material, whereas in refining, the final material is usually identical chemically to the original one, only it is purer The processes used are of many types, including pyrometallurgical and. Western Smelting & Metals Inc is located at the address 1845 Se Holman Ave in Dallas, Oregon They can be contacted via phone at (503) for pricing, hours and directions Western Smelting & Metals Inc has an annual sales volume of 2M – 4,999,999.

METAL SMELTING is a European reference company with more than 30 years of experience in iron casting using various technologies It was created to add value within the Group, taking advantage of the synergies. The advanced metal furnace excavation site near the modernday city of Beersheba, Israel (Talia Abulafia / Israel Antiquities Authority ) During the Beersheba prebuilding survey, an extremely ancient advanced metal furnace for copper smelting and copper slag were discovered, said Talia Abulafia, site excavation director for the Israel Antiquities Authority. Metallurgy and smelting are perhaps some of the most important innovations in human history as they changed transportation, warfare, trade, agriculture, and more Smelting and the working of metals provided a currency system and made the Industrial Revolution from steam to electricity possible.

Tech, industrial, social change;. In its most basic definition, gold smelting can be defined as a process in which gold is purified The gold smelting process uses pressure, high heat, and various chemicals to accomplish this task Smelting your gold will remove impurities and leave you with gold in its purest form. Metal smelting and refining processes generate wastes that may contain multiple hazardous metals, such as lead, zinc, nickel, copper, cadmium, chromium, mercury, selenium, arsenic, and cobalt These elements may be found in the ores used or they may be added as mixed metals into the melts to produce metal alloys.

Smelting is a process of applying heat to ore in order to extract a base metal It is a form of extractive metallurgy It is used to extract many metals from their ores, including silver, iron, copper, and other base metals Smelting uses heat and a chemical reducing agent to decompose the ore, driving off other elements as gases or slag and leaving the metal base behind The reducing agent is commonly a fossil fuel source of carbon, such as coke—or, in earlier times, charcoal The oxygen. Western Smelting & Metals Inc is located at the address 1845 Se Holman Ave in Dallas, Oregon They can be contacted via phone at (503) for pricing, hours and directions Western. During smelting, when the ore is exposed to high temperatures, these impurities are separated from the molten metal and can be removed Slag is the collection of compounds that are removed In many smelting processes, oxides are introduced to control the slag chemistry, assisting in the removal of impurities and protecting the furnace.

And new methods of communication Bronze tin & copper Archaeologists coined the term. Description Metal Smelting is a foundry specialized in grey and nodular cast iron, part of the Metal Group Metal Group is formed by 6 different factories located in the Basque Country (North of Spain) producing Iron Casting parts, machining and subassembling them in order to offer to our customers readytouse solutions. Metal smelting book Book description Description Book description Casting skill Rank5~ Acquisition Shopkeeper Lubeck Lv req Recipe name Ingredient(s) Product 5 1 Make iron recipe info Iron Ore 1 Success Iron 1~2 5 2 Make copper recipe info Copper Ore 1 Success Copper 1~2 5 3 Make lead recipe info.

Smelting, as differentiated from melting, was the first metallurgical operation and is still the principal method of gaining metals from their ores Copper was the first metal to be smelted;. Made by hand with HeavyDuty steel, ceramic wool and refractory to melt most metals Extra thick refractory for long life and extended use No Electricity makes the furnace easier to use Furnace Interior fully lined with 1 inch of ceramic wool, 1 inch refractory. Metal smelting book Book description Description Book description Casting skill Rank5~ Acquisition Shopkeeper Lubeck Lv req Recipe name Ingredient(s) Product 5 1 Make iron recipe info Iron Ore 1 Success Iron 1~2 5 2 Make copper recipe info Copper Ore 1 Success Copper 1~2 5 3 Make lead recipe info.

Respiratory hazards of metal smelting It appears that exposure to emissions of pollutants in the smelting industry is associated with respiratory symptoms, including asthma, lung function decline and chronic obstructive pulmonary disease, depending on the type of production Moreover, it is possible that these exposures may enhance the. Awesome melt today as i melt down a big 43 KG motor and extract all the Copper & Aluminium from it to make a huge haul of Ingots Now guys this motor was des. Smelting is nothing like this Ore is not a mixture of rock and metal The metal itself is often oxidized So you’re not just separating metal and You don’t heat the ore over the fire You actually dump the ore and the fuel together into the furnace and ignite the There are often other.

No, smelting is the process of extracting a metal from its ore Before I started this project I had a very vague notion of what ancient smelting was like I pictured it something like this “ore” is like a rock with some little bits of metal mixed in You make a bonfire and you hold the rock over the fire with, like, tongs or something. NEO Aluminio Colombia plans to build a low carbon primary aluminum production facility in Colombia, which will be named the Green Aluminium Transformation Complex for Colombia (GALTCO) The project — which is intended to reach a capacity of 540,000 tonnes of aluminum per year — will represent the country’s first foray into aluminum smelting. 1 Overview 2 Usage 3 Known Locations 4 Gallery Metal is a resource under the generic Metal type of resources All the nongeneric resources of this type are Cobalt Copper Iridium Iron Silver Tin The various resources within this type are interchangeable for crafting common items For crafting higherquality blueprints, you will need to include two or more of these named resources, but not the.

Tech, industrial, social change;. During smelting, when the ore is exposed to high temperatures, these impurities are separated from the molten metal and can be removed Slag is the collection of compounds that are removed In many smelting processes, oxides are introduced to control the slag chemistry, assisting in the removal of impurities and protecting the furnace. Slag is the glasslike byproduct left over after a desired metal has been separated (ie, smelted) from its raw oreSlag is usually a mixture of metal oxides and silicon dioxideHowever, slags can contain metal sulfides and elemental metals While slags are generally used to remove waste in metal smelting, they can also serve other purposes, such as assisting in the temperature control of.

Rotary Furnace Refining Pot. Smelting is the process of extracting base metals from ore by heating it to produce the chemical reactions needed to remove the other elements present This article will walk through how The Crucible produced their own iron through the smelting of iron ore First, let’s start with understanding the basics What is iron ore?. Made by hand with HeavyDuty steel, ceramic wool and refractory to melt most metals Extra thick refractory for long life and extended use No Electricity makes the furnace easier to use Furnace Interior fully lined with 1 inch of ceramic wool, 1 inch refractory.

Smelt definition, to fuse or melt (ore) in order to separate the metal contained See more. Smelting is the process of extracting base metals from ore by heating it to produce the chemical reactions needed to remove the other elements present This article will walk through how The Crucible produced their own iron through the smelting of iron ore First, let’s start with understanding the basics. We have newage facilities for smelting, casting and cooling of lead metal ingots Our avantgarde units, futuristic R&D centers and advanced testing laboratories ensure top quality of products, consistently Metal Manufacturing Nigeria Ltd Plant;.

Metal smelting furnace coolant cooling, various electrolytic fluid coolers, granulation water cooling, sulfuric acid manufacturing facilities Mining and smelting applications including sufuric acid duty The metal smelting industry is represented by the smelting of copper The Hisaka plate heat exchanger in this industry mainly cools the furnace for melting ores, and cools the electrolyte for electrolytic smelting of raw copper. Electric Furnaces Browse our electric melting furnaces for gold, silver, aluminum, and more With just a few easy steps, start melting your material in as little as 15 minutes!. We have newage facilities for smelting, casting and cooling of lead metal ingots Our avantgarde units, futuristic R&D centers and advanced testing laboratories ensure top quality of products, consistently Metal Manufacturing Nigeria Ltd Plant;.

Smelting obtains a metal at temperatures beyond the melting point from its ore An ore is a naturally occurring material in solid form, from which a metal or valuable mineral is extracted profitably Smelting involves the conversion of ore into its purest form The third process removes metal from the ore that is mined.

Metal Smelting Facility High Res Stock Photo Getty Images

Q Tbn And9gctlnjekcut42o008gpl5gxzgs3e7x4qd5odue16 V4i7iwtecie Usqp Cau

Metal Smelting Furnace In Steel Mills Steel Mill Steel Steel Worker

Metal Smelting Workshop Stock Video Pond5

Metal Smelting Furnace Metal Forging Stock Image Image Of Machine Work

Wallpaper Worker Metal In Liquid Smelter Images For Desktop Section Muzhchiny Download

Smelting And Forging Bloom Iron Youtube

Smelting Definition Facts Britannica

The Ancient Art Of Smelting Iron Anita Chowdry

Replacing Metal Smelting Furnace Electrode Valparaiso Indiana

How To Smelt Iron The 6 Steps To Iron Smelting The Crucible The Crucible

3 961 Metal Smelting Photos Free Royalty Free Stock Photos From Dreamstime

Base Metals To Muddle Through Says Commodity Expert

Gold Smelting Furnace Tilting Induction Metal Melting Equipment For Sale

Iron And Steel Works Metal Stock Footage Video 100 Royalty Free Shutterstock

3 961 Metal Smelting Photos Free Royalty Free Stock Photos From Dreamstime

Electric Metal Melting Furnace 10 50kg Induction Melting Machine

Smelting Of The Metal In The Foundry Factory Worker Takes A Sample For Metal Stock Photo Alamy

What Is A Smelting Pot With Picture

Smelting Furnace 1 Burner Metal Smelting Furnace 10kg Gas Oven Propane 7 Jdbrand

Metal Smelting Furnace In Steel Mills Stock Photo Picture And Royalty Free Image Image

Wallpaper Fire Heat Sparks Molten Metal Smelting Factory Worker Images For Desktop Section Muzhchiny Download

The Ancient Art Of Smelting Iron Anita Chowdry

Hot Smelting Metal Pouring From Ladle Steel And Vector Image

Smelting Wikipedia

Indonesia Metal Mining And Smelter Sector Gbg

Metal For Horseshoes Smelting In Hot Furnace In Blacksmith Workshop On Ranch Adsf Addictive Stock Creatives Westend61

Metal Smelting Steel Image Photo Free Trial Bigstock

Foundry Metal Smelting Plant Stock Photo Picture And Royalty Free Image Image

Iron Smelting Below The Smelting Point

Metal Smelting Casting Stock Photo Edit Now

Metal Smelting Furnace In Steel Mills Stock Photo Picture And Royalty Free Image Image

Plasma Smelting Harsco Environmental

High Purity Melting Graphite Crucible Non Stick Pan For High Temperature Gold And Silver Metal Smelting Tools Long Service Life Metal Graphite Crucible

Premium Photo Metal Smelting Jeweler The Jeweler Pours Out The Ring Silver Firing The Work Of The Master In The Workshop

Experimental Iron Smelting Collected Documentation For The Ongoing Series By Darrell Markewitz In Ontario Canada

Steel And Smelting

Scrap Metal Is Pouring Into The Furnace To Melt And Smelting It Is Used To Extract Many Metals From Their Ores Including Silver Iron Copper And Other Base Metals To Melt Stock

Metal Smelting Stock Photos Offset

Iron Smelting Images Free Vectors Stock Photos Psd

Hard Work In A Foundry Metal Smelting Furnace In Steel Mill Stock Photo Picture And Royalty Free Image Image

Iron And Steel Works Metal Video Stock A Tema 100 Royalty Free Shutterstock

From The Soil To The Iron Product The Technology Of Medieval Iron Smelting Exarc

Metal Smelting Stock Video Footage Royalty Free Metal Smelting Videos Pond5

Precious Metal Smelting Solutions Watsonmelt 18 Years Expert

Induction Heating Melting Furnace Induction Heating Smelter Metal Smelting Equipment China Melting Furnace Induction Furnace Made In China Com

Safe Reliable Extraction Of Casting Fumes Keller Lufttechnik

Industrial Electric Induction Metal Smelting Production Line For Gold Silver Copper Scrap Iron Aluminum Steel Melting China Smelting Production Line Metal Smelting Production Line Made In China Com

Metal Smelting

Metal Smelting Furnace In Steel Mills Stock Photo Download Image Now Istock

Vyksa Russia 12 23 18 Process Of The Metal Smelting With The Martin Furnace Industrial Details Of Metallurgic Fact Stock Photos Photo Editing Army Colors

Amazon Com Usa Cast Master 3 Kg Melting Furnace Smelting Furnace For Foundry Metal Smelter Kiln Kit Gg3000 Kg Crucible Tongs Smelting Recycling Scrap Refining Jewelry Casting Electronic Furnace 1800 Watt 00 Degrees

Smelting Of The Metal In The Foundry Stock Images Page Everypixel

Metal Smelting Furnace In Steel Mill Molten Metal Pouring Metallurgy Steel Casting Foundry By Spocktv

Smelting Of Metal In Big Foundry Iron And Steel Production At A Metallurgical Plant Steel Worker Metallurgy Process Canstock

Iron Ore Smelting Process Bright Hub Engineering

Industrial Electric Induction Metal Smelting Plant For Gold Silver Scrap Copper Iron Steel Aluminum Melting China Smelting Plant Induction Smelting Plant Made In China Com

Slag From Metals By Product To Valuable Construction Material

Smelting Of Metal In Big Foundry Iron And Steel Production At A Metallurgical Plant Steel Worker Metallurgy Process Canstock

Smelting Morgan Mill Metals

1

China Hot Selling Environmental kg Aluminum Metal Smelting Furnace Jlz 45 China Furnace Metal Smelting Furnace

Smelting Science 5 Smelting Details 2

Smelting Metal In Steel Mill Smelting Metal In A Metallurgical Plant Liquid Iron From The Ladle Canstock

Smelting Of The Metal In The Foundry Metallurgical Products Stock Photo Alamy

Smelting Of Metal In Big Foundry Iron And Steel Production At A Metallurgical Plant Steel Worker Metallurgy Process

High Temperature Proof Metal Smelting Industry Cable Reel Powered Ladle Car

What Is Smelting

Blast Furnace Metal Smelting Steel And Alloys Vector Image

State Metal Industries What Is Smelting

Metal Smelting Casting Stock Photo Picture And Royalty Free Image Image

Blacksmithing Iron Smelting And Forging A Poor Bloom Youtube

Brave Investors Should Consider Mining And Metals Again

Metal Smelting Images Free Vectors Stock Photos Psd

1

Five Things You Didn T Know About Smelting

China S Aluminum Smelters Alone Could Shift 2 3 Of Daily Electricity Demand Pv Magazine International

Metal Smelting Furnace In Steel Mills Stock Photo Picture And Royalty Free Image Image

Smelting Of The Metal In The Foundry Metallurgical Industry Stock Photo C Davit85

Hot Ore In A Steel Trough Metal Smelting Plant Stock Image Image Of Factory Heavy

Metal Smelting In Foundry Powerpoint Template Backgrounds Google Slides Id Smiletemplates Com

Metal Smelting Casting Stock Photo Picture And Royalty Free Image Image

The Large Metal Smelting Furnace And The Workers Are Working Smelting Is A Process Of Applying Heat To Ore In Order To Extract Out A Base Metal It Is A Form Of

Q Tbn And9gcriy5w 8chzmcs5jfg2i2xjhrofswhci1kbg5123fwmltr8ghwj Usqp Cau

Vyksa Russia 12 23 18 Process Of The Metal Smelting With The Martin Furnace Industrial Detai In Social Media Design Graphics Stock Illustration Stock Photos

Metal Smelting High Frequency Induction Heating Machine 15kw Quenching Annealing Welding Metal Heat Treatment Equipment 2v Buy Metal Smelting High Frequency Induction Heating Machine 5kw Quenching Annealing Welding Metal Heat Treatment

The Future Of Smelting Technology Usc Consulting Group

From Dirt To Space Backyard Iron Smelting Hackerspace Style Hackaday

10 2 2 Smelting Iron

Have A Look At New And Better Way To Make Metal Newsbharati

Scr Medium Frequency Scrap Iron Metal Induction Smelting Furnace China Scrap Iron Melting Furnace Metal Melting Furnace Made In China Com

Metal Smelting Casting Stock Photo C Dushlik

Metal For Horseshoes Smelting In Hot Furnace In Blacksmith Workshop On Ranch Adsf Addictive Stock Creatives

Smelting Base Metal Smelting

Smelting Of Metal In Big Foundry Iron And Steel Production At A Metallurgical Plant Steel Worker Metallurgy Process Canstock

How To Smelt Iron The 6 Steps To Iron Smelting The Crucible The Crucible

Metal Smelting Stock Photos Offset

Metal Smelting Iron Casting And Machining Ready To Use Solutions Linkedin